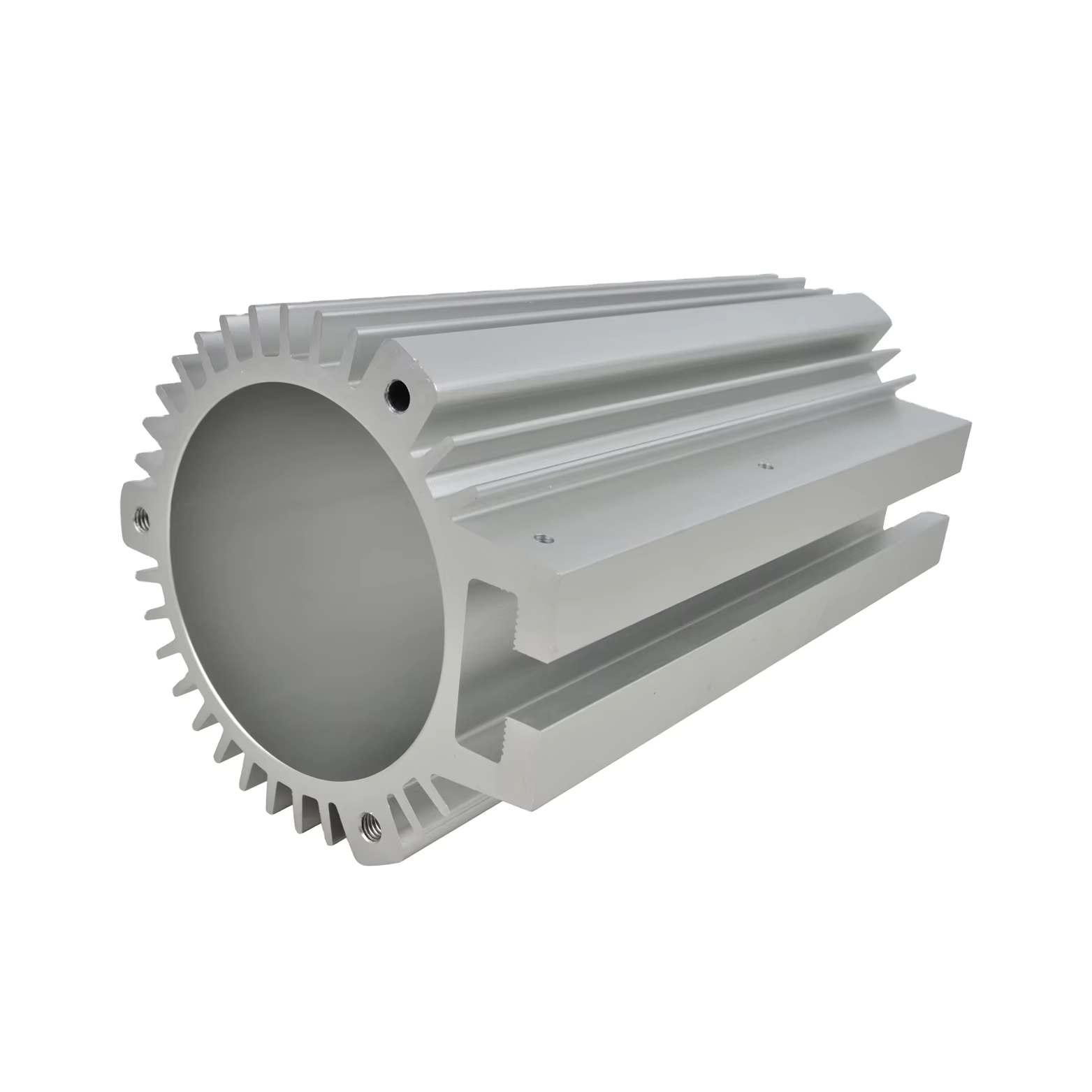

Introduction to Aluminum Extrusion Motor Casing

Aluminum extrusion motor casings are critical components in modern machinery, offering a blend of lightweight durability, thermal efficiency, and design flexibility. Made through the extrusion process—where heated aluminum is forced through a die to create complex cross-sectional profiles—these casings are widely used in automotive, industrial automation, and renewable energy systems. This blog explores their advantages, manufacturing techniques, and key design considerations to help you optimize your next project.

Why Choose Aluminum Extrusion for Motor Casings?

Lightweight & High Strength-to-Weight Ratio

Aluminum’s low density reduces system weight by up to 60% compared to steel, improving energy efficiency in applications like electric vehicles and robotics18.

- Superior Thermal Conductivity

Efficient heat dissipation prevents motor overheating, extending lifespan and performance. This is critical for high-power industrial motors and EV battery housings8. - Corrosion Resistance

Natural oxide layer formation protects against environmental wear, ideal for outdoor or marine applications16. - Design Flexibility

Extrusion allows complex geometries (e.g., integrated cooling fins, mounting slots) without costly machining89. - Sustainability

Recyclable and energy-efficient to produce, aligning with eco-friendly manufacturing trends68.

Manufacturing Process of Aluminum Extrusion Motor Casings

Material Selection

Common alloys like 6061-T6 (general use) or 7075 (high-stress aerospace applications) are chosen for their balance of strength and machinability26.

- Heating & Extrusion

- Aluminum billets are heated to 400–500°C and forced through a precision die under high pressure (up to 15,000 tons)8.

- Controlled cooling (air or water) stabilizes the structure and minimizes distortion89.

- Post-Processing

- Aging (T5/T6 treatment): Enhances hardness and mechanical properties8.

- Surface finishing: Anodizing or powder coating improves corrosion resistance and aesthetics68.

- Quality Control

Advanced techniques like ECAP (Equal Channel Angular Pressing) ensure uniform grain structure and dimensional accuracy210.

Key Applications

Electric Vehicles (EVs): Lightweight casings for battery enclosures and drive motors68.

- Industrial Automation: Durable housings for robotic arms and CNC machinery18.

- Renewable Energy: Heat-resistant casings for wind turbine generators and solar inverters8.

- Consumer Electronics: Compact designs for drones and HVAC systems8.

Design Considerations for Optimal Performance

Alloy Selection

High-strength alloys like Al-Zn-Mg-Cu (e.g., 7075) are preferred for extreme loads, while 6061 suits cost-sensitive projects68.

- Wall Thickness & Geometry

- Balance between weight reduction and structural integrity. Thin walls (1–3 mm) are achievable with precise die design9.

- Integrated fins or channels enhance heat dissipation8.

- Tolerance & Surface Finish

Tight tolerances (±0.1 mm) ensure compatibility with internal components. Anodized finishes add wear resistance810. - Cost Efficiency

Minimize post-processing by leveraging extrusion’s near-net-shape capabilities8.

Industry Trends & Innovations

Smart Casings: Embedded sensors for real-time temperature and vibration monitoring5.

- Hybrid Composites: Aluminum-carbon fiber blends for ultra-lightweight solutions6.

- Additive Manufacturing: 3D-printed dies for rapid prototyping of complex profiles10.

CTA: Ready to revolutionize your motor systems with precision aluminum casings? [Contact our engineers] for a free consultation or download our technical guide on extrusion best practices!

Links:

IEEE