The relentless pursuit of efficiency, performance, and cost-effectiveness drives constant innovation in the motor industry. While aluminum die-cast components have long been staples, aluminum extruded profiles are rapidly gaining ground, becoming the preferred choice for many critical applications. This shift isn’t accidental; it’s driven by the unique advantages extrusions offer in meeting the evolving demands of modern motor design.

Why Aluminum Reigns Supreme in Motors

Before diving into the extrusion vs. die-casting debate, let’s recall why aluminum is indispensable:

- Lightweight: Reduces overall system weight, crucial for EVs, drones, robotics, and portable tools, boosting energy efficiency and performance.

- Thermal Conductivity: Excellent heat dissipation protects sensitive windings, magnets, and electronics, enhancing reliability and lifespan.

- Corrosion Resistance: Naturally protective oxide layer ensures durability in various environments.

- Good Strength-to-Weight Ratio: Provides structural integrity without excessive bulk.

- Electrical Shielding (when needed): Can be designed or treated to provide EMI/RFI shielding.

- Machinability & Recyclability: Easy to work with and environmentally friendly.

Die-Casting: The Traditional Powerhouse

Aluminum die-casting involves forcing molten aluminum under high pressure into a reusable steel mold (die). It excels at producing complex, near-net-shape 3D geometries with high dimensional accuracy and excellent surface finish, ideal for intricate housings, end-bells, brackets, and complex structural parts in high-volume production.

Die-Casting Advantages:

- Complex Geometries: Creates intricate shapes (ribs, bosses, undercuts) difficult or impossible with extrusion.

- High Production Speed: Extremely fast cycle times for massive volumes.

- Dimensional Accuracy & Surface Finish: Excellent as-cast precision and finish, often reducing secondary machining.

- Material Utilization: Minimal waste for complex parts compared to machining from solid.

Die-Casting Limitations:

- High Tooling Cost: Complex steel dies are extremely expensive, making low-to-medium volume production uneconomical.

- Porosity Risk: Trapped air/gas can create internal voids, potentially compromising structural integrity or pressure tightness.

- Limited Mechanical Properties: Typically produces lower strength (especially elongation) compared to wrought alloys like extruded profiles. Heat treatment options are often limited.

- Design Inflexibility: Significant design changes require expensive and time-consuming die modifications.

- Wall Thickness Constraints: Very thin walls are challenging; thick sections risk shrinkage defects.

- Part Size Limitations: Practical size is constrained by die size and press capacity.

The Rise of Aluminum Extrusions: Why the Shift?

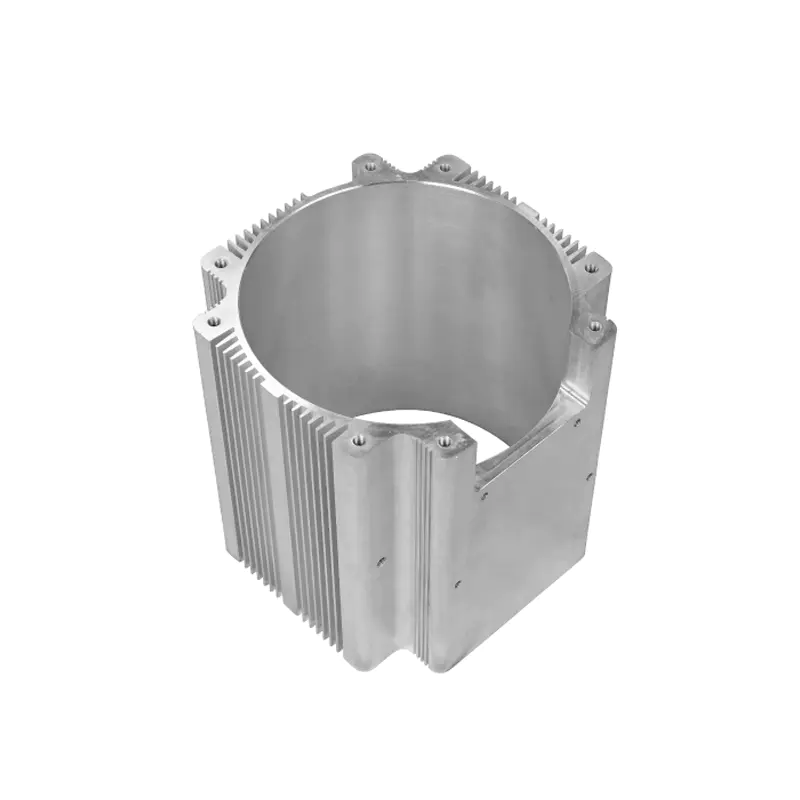

Aluminum extrusion involves heating a solid aluminum billet and forcing it through a shaped die to create a continuous profile with a constant cross-section. This process is proving uniquely advantageous for modern motor components.

Extrusion Advantages Driving Adoption:

- Superior Strength & Consistency:

- Extruded profiles use wrought alloys (like 6000-series – 6061, 6063) that are significantly stronger and tougher than typical die-casting alloys (like A380). They offer higher tensile strength, yield strength, and crucially, much better elongation (ductility), making them less brittle and more impact-resistant.

- The process inherently produces a denser, more homogenous structure with minimal porosity, resulting in predictable mechanical properties and better pressure tightness.

- Unmatched Design Flexibility (in 2D):

- While limited to a constant cross-section, extrusion dies are relatively inexpensive and quick to produce compared to die-casting dies.

- This allows for highly customized profiles tailored to specific motor needs: integrated cooling fins/channels, mounting rails, wireways, sensor cavities, and optimized structural shapes. Design iterations are fast and cost-effective.

- Exceptional Thermal Management:

- This is a major driver. Extrusions allow the direct integration of complex, high-surface-area heat sinks and coolant channels into the profile itself (e.g., motor housings, end plates). This is vastly more efficient than attaching secondary heat sinks to a die-cast part, leading to significantly better heat dissipation – critical for high-power-density motors in EVs and industrial drives.

- Cost-Effectiveness for Medium Volumes & Customization:

- Lower tooling costs make extrusions economically viable for medium production runs and highly customized applications where die-casting tooling would be prohibitive.

- Reduced Secondary Operations: Profiles can be designed to minimize machining. Simple cutting, drilling, tapping, and notching are often sufficient.

- Material Efficiency & Lightweighting:

- Extrusions allow for precise placement of material only where strength or function is needed (e.g., thicker walls around bearings, thinner fins elsewhere), optimizing the strength-to-weight ratio.

- Integrated functions (structure + cooling + mounting) eliminate the need for multiple separate parts, reducing weight and assembly complexity.

- Longer Parts & Structural Integration:

- Extrusions can be produced in very long lengths, ideal for linear motors, long motor housings, or frames integrating multiple components.

- They excel as structural frames or enclosures that house the entire motor assembly, providing rigidity and mounting points.

Where Die-Casting Still Holds Its Ground:

Despite the strong trend towards extrusions, die-casting remains vital for:

- Highly complex 3D shapes requiring features on multiple planes (e.g., intricate gearbox housings, complex end caps with internal features).

- Very high-volume production where the high tooling cost is amortized effectively (e.g., millions of small appliance motors).

- Applications where the specific alloys or as-cast surface finish of die-casting are critical.

The Verdict: A Clear Trend Towards Extrusion

The motor industry’s trajectory is clear: aluminum extrusions are increasingly displacing die-castings, particularly for housings, frames, heat sinks, and structural components where strength, thermal performance, design flexibility for cooling, and cost-effectiveness at medium volumes are paramount. The ability to create integrated, high-performance thermal solutions directly within the profile structure is a game-changer for modern, power-dense motors.

Choosing the Right Process:

The optimal choice always depends on the specific part requirements:

- Choose Extrusion for: Housings with integrated cooling, structural frames, heat sinks, long components, medium volumes, applications demanding high strength/ductility, cost-sensitive customization.

- Choose Die-Casting for: Highly complex 3D shapes, very high volumes where tooling cost per part is low, intricate small parts, applications where die-cast alloy properties suffice.

Conclusion

Aluminum extrusions are not just an alternative; they are becoming the foundation for next-generation motor design. Their superior strength, exceptional thermal management capabilities, remarkable design flexibility for critical functions like cooling, and cost advantages for customization and medium-scale production are compelling reasons for their surging popularity. As motors continue to evolve towards higher power densities, greater efficiency, and tighter integration, the inherent advantages of extruded aluminum profiles position them as the material and process of choice, steadily outmaneuvering traditional die-cast solutions in an ever-growing number of applications. The future of motor construction is increasingly taking shape through the extrusion die.

Links:

IEE

Contact for a quote