Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Electric Vehicle Drivetrains: Enhance performance and longevity of EV traction motors. See our EV cooling solutions.

Industrial Servo & Stepper Motors: Maintain precision in automation and manufacturing.

UAV & Aerospace Motors: Critical for high-altitude and high-performance applications.

Robotic Joint Actuators: Enable compact, powerful robotic designs.

Renewable Energy Generators: Improve reliability in wind turbine and hydro generators.

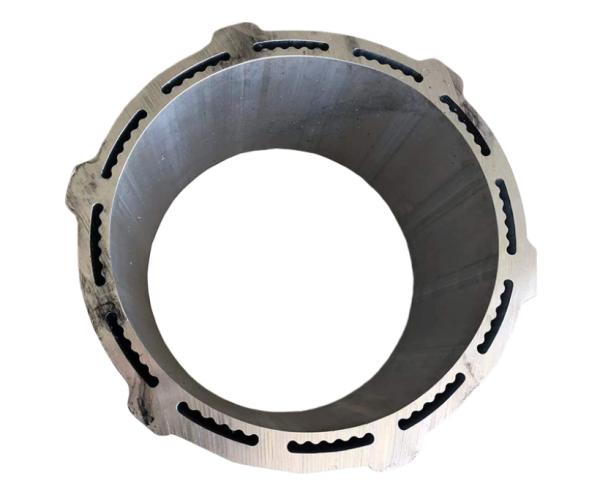

The Water-Cooled Aluminum Motor Casing is an advanced thermal management solution designed for high-power-density electric motors. Engineered with premium aluminum alloy and an efficient internal cooling channel layout, it ensures optimal operating temperatures under extreme conditions, enhancing motor efficiency, reliability, and service life. Ideal for electric vehicles, industrial motors, aerospace applications, and precision robotics.

Explore our full range of motor cooling solutions and industrial thermal management products.

Optimized internal water-flow channels improve heat dissipation efficiency by 300% compared to traditional air cooling

Made with high-grade Aluminum 6061-T6, offering excellent thermal conductivity (167 W/m·K)

Anodized surface treatment enhances heat radiation and corrosion resistance

Learn more about how our cooling technology works or compare with air-cooled alternatives.

CNC-machined to tight tolerances (±0.05mm)

Modular design compatible with various motor sizes and types

Leak-proof design, tested up to 0.8MPa operating pressure

Discover our manufacturing capabilities and quality assurance process.

| Parameter | Specification |

|---|---|

| Material | Aluminum 6063-T6 |

| Cooling Capacity | 500W – 2000W (model dependent) |

| Operating Temperature | -40°C to +150°C |

| Protection Rating | IP67 (IP68 optional) |

| Standard Sizes | Multiple options available, custom designs welcome |

| View our detailed specification sheet (PDF) or contact us for custom requirements. |

Electric Vehicle Drivetrains: Enhance performance and longevity of EV traction motors. See our EV cooling solutions.

Industrial Servo & Stepper Motors: Maintain precision in automation and manufacturing.

UAV & Aerospace Motors: Critical for high-altitude and high-performance applications.

Robotic Joint Actuators: Enable compact, powerful robotic designs.

Renewable Energy Generators: Improve reliability in wind turbine and hydro generators.

Read our case studies on how we’ve helped clients in these industries.

Our engineers use Computational Fluid Dynamics (CFD) simulation to optimize coolant flow paths, ensuring even heat distribution and eliminating hot spots. The proprietary turbulator-enhanced design increases heat exchange efficiency by over 40%.

The aluminum construction provides exceptional strength while being 60% lighter than traditional steel housings, contributing to higher system power density and energy efficiency.

From standard models to fully bespoke designs, we tailor solutions to your specific thermal, spatial, and performance requirements. Start your custom design inquiry today.

Each unit undergoes pressure testing, leak detection, and thermal performance validation. Our manufacturing is ISO 9001 certified. Learn about our quality standards.

For a deeper dive, read our technical article: The Engineering Behind Effective Motor Cooling.

Compared to traditional cooling methods, our water-cooled aluminum casing delivers:

More stable temperature control (±5°C variation)

Up to 30% longer motor lifespan

Enables sustained high-torque operation

Allows for more compact and lighter motor designs

Standardized mounting interfaces for easy integration

Compatible with most common cooling system components

Comprehensive installation guides and dedicated technical support

Optional integrated temperature sensors and flow monitoring ports

Access our installation manuals and technical support portal.

100% recyclable materials

Energy-efficient manufacturing processes

Long-life design reduces waste and resource consumption

Fully RoHS compliant

Our sustainability initiative details our environmental goals.

Q: Is leakage a concern with water-cooled systems?

A: Our multi-stage sealing design and stringent quality testing ensure a leak rate below 0.01% for long-term reliability.

Q: Do you support low-volume custom orders?

A: Yes, we offer full support from prototyping to production, with minimum order quantities as low as 50 units for custom designs.

Q: What is the typical lead time?

A: Standard models are in stock and ship within 3-5 business days. Custom designs typically require 4-6 weeks, depending on complexity.

Q: How do I select the right model for my application?

A: Please provide your motor power, size constraints, and thermal requirements. Our engineering team will recommend the optimal solution. Use our product selection guide or request a consultation.

Looking for a high-performance motor cooling solution? Our engineering team is ready to provide expert consultation and a tailored proposal.

✉️ Email:project@hiqalum.com

Reviews

There are no reviews yet.