Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

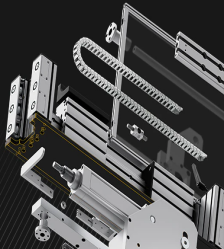

When it comes to aluminum profile, there are actually many types, including industrial profiles, door and window profile, building profiles, decoration aluminum profiles, aerospace profiles, medical profiles, and so on.

As is well known, the hardness of unprocessed aluminum profiles is very low, and mechanical activity equipment and assembly countertops require the use of aluminum profiles. How can aluminum profiles withstand loads without changing the shape of Guangdong decorative profiles? In fact, profiles are not worth abandoning in the case of twists and turns, and can be avoided. So, how to reduce or avoid aluminum profiles caused by twists and turns and waste.

(1) What can extruded aluminum profiles do: eliminate the metal stress generated during the extrusion process, control the size of aluminum profiles, industrial profiles refer to all profiles except for building doors and windows, curtain walls, indoor and outdoor decoration, and building structures.

(2) Squeeze straightening: Straightening is a very important process caused by the bending of profiles. The straightening industry must pay attention to the strength used during the straightening process. If the straightening strength is too large, it may cause deformation, closure, orange peel, etc. If the strength is too small, the profile will not be straightened, creating twists. Industrial profiles refer to all profiles except for building doors and windows, curtain walls, indoor and outdoor decorations, and building structures.

(3) Squeezing frame: This link is also very important. After sawing off a certain length of profiles, the profiles will be loaded. At this time, the frame worker will pay attention to whether it is large or small materials, is the material with pipeline materials or flat molds pulled out? Individually, the lifting frame of large materials and pipeline materials is not easy to cause twists and turns at both ends, but the lifting of small materials and materials pulled out from flat molds can easily cause twists and turns at both ends, At this point, the lifting frame for Guangdong decorative profiles should be assembled from both ends to one side.

Links