Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Product Overview

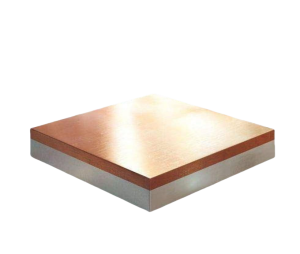

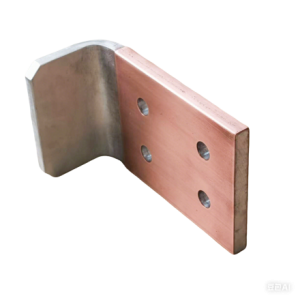

Our Aluminum-Copper Bimetal seamlessly combines the lightweight versatility of aluminum with the unmatched conductivity of copper, engineered for applications demanding superior heat dissipation, electrical performance, and structural reliability. Precision-bonded through explosive welding or roll-cladding technology, this hybrid material eliminates compromises, delivering optimized solutions for power electronics, EV components, and high-frequency systems.

Superior Thermal Management

Thermal Conductivity: 220 W/m·K (aluminum layer) + 400 W/m·K (copper layer)

Ideal for heat sinks, busbars, and battery connectors requiring rapid heat transfer.

High Electrical Efficiency

Low Resistivity: Copper layer ensures <0.017 Ω·mm²/m for minimal energy loss in high-current applications.

Weight Reduction

50% lighter than full-copper designs while maintaining 90% of its conductivity.

Galvanic Corrosion Resistance

Proprietary interface bonding prevents oxidation, certified for 1,000+ hours in salt spray (ASTM B117).

Customizable Configurations

Thickness ratios (Al:Cu) from 1:1 to 10:1

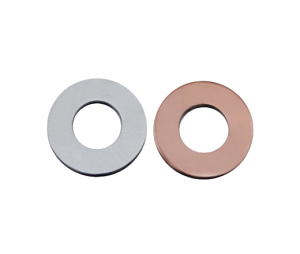

Available in sheets, rods, or complex stamped shapes.

| Parameter | Details |

|---|---|

| Bonding Method | Explosive Welding / Roll Bonding |

| Aluminum Alloy | 1050, 6061, or Custom Grades |

| Copper Alloy | C11000 (ETP), C10200 (OFHC) |

| Thickness Range | 0.5mm – 50mm (Total) |

| Sheet Size | Up to 1,200mm x 2,500mm |

| Surface Finish | Mill, Polished, or Anodized (Al side) |

Electric Vehicles: Battery interconnect systems, inverter cooling plates

Renewable Energy: Solar PV junction boxes, wind turbine busbars

Electronics: IGBT baseplates, LED heat sinks, RF shielding

Industrial: Welding electrodes, transformer laminations

Zero-Delamination Guarantee: Rigorous ultrasonic testing (UT) ensures bond integrity.

High-Volume Readiness: Laser cutting and CNC stamping lines support mass production (MOQ: 100kg).

RoHS & REACH Compliance: Free from hazardous substances, 100% recyclable.

DFM Support: Our engineers optimize designs for cost and performance—submit your CAD file for a free review.

A global EV supplier reduced thermal resistance by 40% using our Al-Cu bimetal (3:1 ratio), achieving:

Continuous Current: 500A without overheating

Weight Savings: 2.8kg per unit vs. solid copper

Cost Reduction: 25% lower material expense

ISO 9001:2015 Certified Production

100% Eddy Current Testing for Layer Uniformity

Lot Traceability via Blockchain-Based Documentation

Prototyping: 5-day lead time for samples (max. 500x500mm)

Custom Alloys: Add magnesium, silicon, or nickel for enhanced properties

Global Logistics: FOB, CIF, or DDP terms available

Download Resources:

Have Questions?

Contact our material science team at project@hiqalum.com

Innovate with confidence—where aluminum’s lightness meets copper’s power.