Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

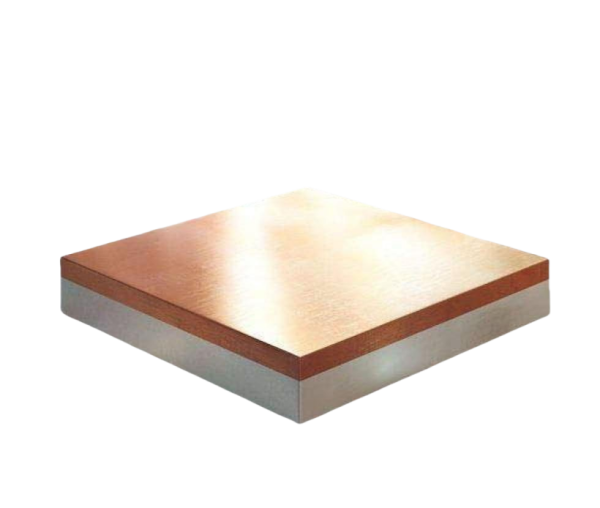

Unlock the power of hybrid engineering with our Aluminum Copper Bimetal solutions, designed to deliver unmatched heat dissipation, electrical efficiency, and structural integrity in demanding applications. By seamlessly bonding lightweight aluminum with high-conductivity copper, we create a material that outperforms traditional metals, reducing energy loss and extending component lifespan.

Unlock the power of hybrid engineering with our Aluminum Copper Bimetal solutions, designed to deliver unmatched heat dissipation, electrical efficiency, and structural integrity in demanding applications. By seamlessly bonding lightweight aluminum with high-conductivity copper, we create a material that outperforms traditional metals, reducing energy loss and extending component lifespan.

Key Features:

⚡ Optimized Conductivity: Combines copper’s exceptional electrical/thermal properties with aluminum’s lightweight corrosion resistance.

⚡ Durable Clad Bonding: Explosion-welded or rolled-bonded interface ensures zero delamination under extreme temperatures (-200°C to 300°C).

⚡ Custom Geometry: Tailor thickness ratios (Al:Cu from 1:1 to 10:1), shapes, and surface finishes for your application.

⚡ Corrosion Resistance: Aluminum layer protects copper core from oxidation in harsh environments.

⚡ Cost Efficiency: Reduce material costs by strategically using copper only where conductivity is critical.

Applications:

Power electronics (IGBT modules, busbars, inverters)

EV battery terminals and charging connectors

Heat sinks for high-power LEDs and semiconductor devices

Solar panel junction boxes and transformer components

HVAC heat exchangers and refrigeration systems

Aerospace and defense electrical systems

Why Choose Our Aluminum Copper Bimetal?

✅ Advanced Bonding Technology: Proprietary processes ensure >99% interfacial bonding strength (tested to ASTM E8).

✅ Precision Machining: Laser cutting, CNC milling, and stamping services for ready-to-install components.

✅ Global Compliance: Meets RoHS, REACH, and MIL-STD-202 standards.

✅ Prototyping Support: Functional prototypes delivered in 5–7 days to validate performance.

Technical Specifications:

Material Composition: 1050/1060 Aluminum + C11000 Copper (custom alloys available)

Bonding Method: Explosive welding, cold rolling, or hot rolling

Electrical Conductivity: 85–98% IACS (adjustable via Cu layer thickness)

Thermal Conductivity: 200–350 W/m·K

Thickness Range: 0.5mm–50mm (total)

Standard Sheet Size: 1000mm x 2000mm (custom dimensions available)

Custom Solutions for Hybrid Performance

Need transition joints, stamped parts, or multi-layer laminates? Our engineers optimize the Al/Cu ratio and geometry to balance weight, conductivity, and cost for your project.

FAQs

Q: Can this bimetal be welded to pure aluminum or copper parts?

A: Yes! We provide pre-bonded transition zones for seamless welding compatibility.

Q: Is the bimetal suitable for high-frequency applications?

A: Absolutely – Copper’s RF shielding properties combined with aluminum’s weight savings make it ideal for RF components.

Q: Do you offer anti-oxidation coatings?

A: Optional nickel plating or chromate conversion coatings available for enhanced durability.

Q: What’s the MOQ for custom orders?

A: Prototype MOQ starts at 10kg; contact us for volume pricing.

Bridge Efficiency & Cost – Innovate with Bimetal Mastery!

[Request a Free Sample] [Download Technical Guide]