Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

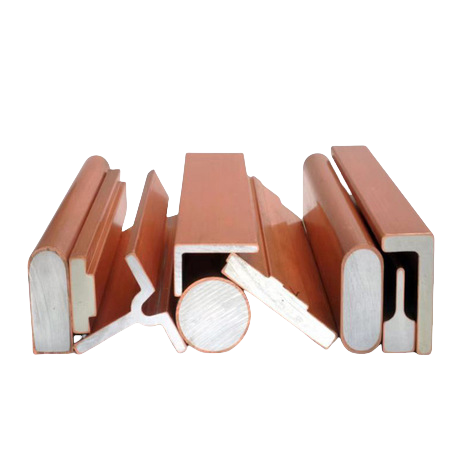

Revolutionize your electrical and thermal systems with our Aluminum Copper Bimetal Clad Strips, engineered to eliminate electrochemical corrosion while combining the best properties of copper and aluminum. Perfect for high-performance applications in energy, automotive, and industrial sectors, our clad strips deliver unmatched reliability and cost savings.

Revolutionize your electrical and thermal systems with our Aluminum Copper Bimetal Clad Strips, engineered to eliminate electrochemical corrosion while combining the best properties of copper and aluminum. Perfect for high-performance applications in energy, automotive, and industrial sectors, our clad strips deliver unmatched reliability and cost savings.

Key Advantages & Features:

⚡ Electrochemical Corrosion Resistance

Proprietary bonding technology neutralizes galvanic potential differences, preventing oxidation (Al₂O₃ formation) and ensuring safe electrical transitions.

Ideal for humid, high-current environments where pure copper or aluminum alone would degrade.

⚡ Dual Performance Excellence

High Electrical Conductivity: Copper layer ensures efficient current transfer (up to 85% IACS).

Superior Thermal Dissipation: Aluminum layer rapidly disperses heat, reducing hotspots.

⚡ Lightweight & Cost-Effective

50-70% lighter than pure copper, slashing material and logistics costs.

Strategic copper placement optimizes conductivity without full copper weight.

Applications:

🔌 Energy & Automotive:

EV Battery Systems: Cell tabs (soft-pack battery ears), cell interconnects, module busbars, terminal connectors.

Power Distribution: Transformer/reactor busbars, cable joints, bus ducts, switchgear shunts.

Renewable Energy: Solar inverter links, battery storage interconnects.

🔌 Electronics & Industrial:

High-Power LED: Heat sinks, thermally conductive substrates, PCB baseplates.

Electrolysis Plants: Corrosion-resistant anode/cathode connectors.

Decorative Architecture: Lightweight façade panels, copper-aluminum composite decor (windows, cutlery).

Technical Specifications:

Material: 1060/3003 Aluminum + T2 Copper Clad

Bonding Method: Explosive welding or rolling (shear strength ≥100 MPa)

Conductivity: 30-45 MS/m (adjustable via Cu/Al thickness ratio)

Thickness: 0.5mm–10mm (Cu layer: 10%–50% of total thickness)

Width: 10mm–500mm

Surface Treatment: Anti-oxidation coating, tin/nickel plating (optional)

Why Choose Our Aluminum Copper Bimetal Clad Strips?

✅ Zero Delamination Guarantee: Rigorous ASTM B898 testing ensures lifelong bonding integrity.

✅ Custom Ratios & Shapes: Tailor copper-aluminum thickness ratios, widths, and hole patterns.

✅ Certified Compliance: RoHS, REACH, and UL standards met for global markets.

✅ Rapid Prototyping: Functional samples delivered in 5 days.

FAQs

Q: How do you prevent galvanic corrosion at the Cu/Al interface?

A: Our proprietary interlayer diffusion barrier eliminates ionic migration, validated by 1,000-hour salt spray tests.

Q: Can these strips replace solid copper busbars in high-current applications?

A: Yes! Optimized Cu/Al ratios maintain ampacity while reducing weight and cost by up to 60%.

Q: Do you provide welding guidelines for battery cell connections?

A: Absolutely – Download our laser/ultrasonic welding manual or request on-site training.

Q: What’s the MOQ for custom sizes?

A: Prototype MOQ: 50kg; bulk orders start at 1 ton.

SEO-Optimized Title & Keywords:

Title: Aluminum Copper Bimetal Clad Strips | Corrosion-Resistant Busbars for EV & Energy

Primary Keywords: Aluminum Copper Bimetal, Copper-Aluminum Composite Strips, Electrochemical Corrosion Resistance, EV Battery Busbars, Bimetal Clad Busbars

Secondary Keywords: Thermal Conductive Clad Material, Lightweight Electrical Connectors, Copper-Aluminum Composite Applications

CTA Section

[Request Free Sample Kit] [Download Welding Guidelines] [Get Custom Quote]